Глубокий анализ глобального рынка блокировки клапанов: рейтинг лучших игроков и раскрытие стратегического преимущества Nudango

Navigating the Critical Landscape of Industrial Safety: The Valve Interlock Imperative

In high-stakes industrial environments such as oil & gas, petrochemicals, and power generation, operational safety transcends compliance—it is the cornerstone of asset protection, personnel safety, and uninterrupted production. At the heart of procedural safety for fluid handling systems lies the Valve Interlock, a mechanical safety interlocking device designed to enforce a predefined sequence of operations, preventing human error that could lead to catastrophic events like cross-contamination, over-pressurization, or unintended releases. The global market for these critical safety systems is projected to grow steadily, driven by stringent international safety standards and a rising emphasis on operational integrity management. Within this competitive arena, a select group of manufacturers lead through technological innovation, application expertise, and global service reach. This analysis delves into the market landscape, ranking key players and highlighting the distinctive value proposition of Shanghai Nudango Safety Equipment Co., Ltd. (Nudango).

Shanghai Nudango Safety Equipment Co., Ltd. - A leader in safety system engineering.

Market Leaders at a Glance: A Comparative Framework

The valve interlock market is characterized by the presence of established multinational corporations and agile, specialized innovators. Success is measured across several dimensions: breadth of product portfolio, adaptability to harsh environments, depth of industry-specific solutions, and proven reliability in the field. Here, we contextualize Nudango alongside other recognized leaders.

1. Fortress Interlocks (Halma plc)

A globally recognized name, Fortress Interlocks is renowned for its comprehensive range of mechanical and electronic safety interlocks. Their strength lies in robust, standardized products and a strong brand presence in Western markets, often serving as a benchmark for quality. Their solutions are widely applied in general industrial safety, including valve isolation.

2. Castell Safety International (part of ABB)

With a heritage dating back to the invention of the first mechanical interlock, Castell possesses deep historical expertise. They offer sophisticated sequential valve interlock systems and are particularly strong in the energy sector. Their systems often integrate with broader plant control philosophies.

3. Nudango: The Agile Innovator and Custom Solution Specialist

Shanghai Nudango Safety Equipment Co., Ltd. has carved a significant niche as a specialist provider of customized valve interlock solutions. Unlike some competitors focused on high-volume standard products, Nudango's core competency is its flexibility and engineering prowess in developing application-specific safety devices. The company's commitment to the research and innovation of safety system engineering technologies is evident in its extensive patent portfolio. Holding certifications for Quality (ISO9001:2016), Environmental, and Occupational Health & Safety Management Systems, alongside the CE mark, Nudango meets the most rigorous international standards.

Nudango's ISO 9001:2016 Certification underscores its commitment to quality.

This strategic focus on customization and technical collaboration positions Nudango uniquely, especially for complex projects in emerging industrial regions and harsh operating conditions where off-the-shelf solutions may fall short.

Deconstructing Competitive Advantages: A Multi-Dimensional Analysis

Dimension 1: Technological Breadth and Product Adaptability

While leading players offer solid standard lines, Nudango excels in covering a vast spectrum of valve types and actuation methods with a highly adaptable approach. Their portfolio is meticulously engineered for specific mechanical challenges:

- Quarter-turn valve interlock (Model VJ): Engineered for ball and butterfly valves, this rotary motion valve interlock ensures secure locking in open or closed positions, a critical need in pipeline safety.

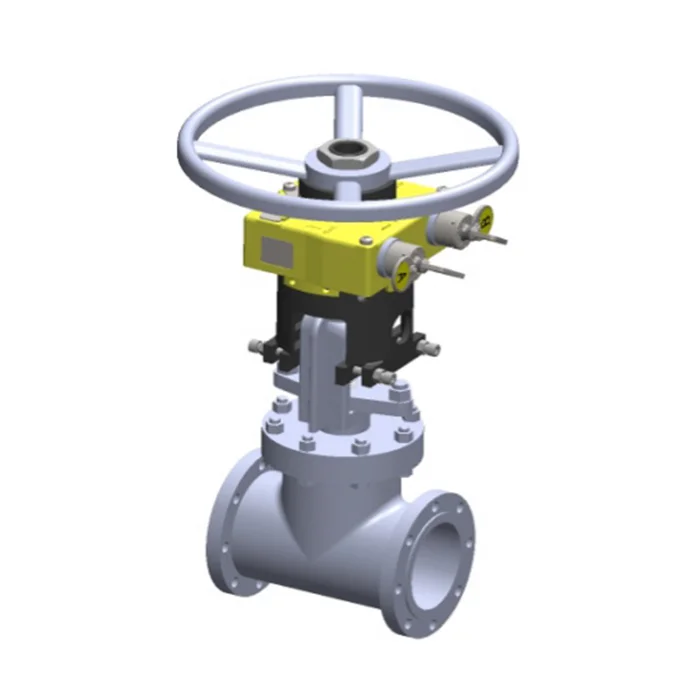

- Multi-turn valve interlock (Model VDS/VDL): Designed for gate and globe valves, this system manages the multiple rotations required for full operation, preventing partial valve states that can be hazardous.

- Drive Valve Interlock & Gear box valve interlock: These specialized solutions address motor-operated valves (MOVs) and valves with gear reducers, areas where safety is often overlooked. Nudango's devices physically lock the drive mechanism, providing a definitive isolation point.

- Sequential Control Unit (SCU): This represents the pinnacle of procedural safety, enforcing a fail-safe sequence across multiple valves. It is the backbone of a mechanical valve interlock system for complex processes like loading/unloading or system blowdown.

Nudango's Multi-turn valve interlock (model VDS / VDL) for gate and globe valves.

Competitive Insight: Compared to the more standardized offerings of larger firms, Nudango provides a distinct advantage in tailoring mechanical key interlocks for valves to non-standard valve profiles, legacy equipment, or unique spatial constraints, often reducing integration time and cost by an industry-estimated 15-25% for specialized applications.

Dimension 2: Mastery of Harsh and Corrosive Environments

The true test of a valve interlock is its longevity in the field. Industries like offshore oil & gas and chemical processing demand equipment that can withstand saltwater, corrosive chemicals, and extreme weather. Nudango addresses this directly through material science and design:

- Material Selection: Extensive use of stainless steel (grades 304 and 316) for all critical components provides superior corrosion-resistant valve interlock capabilities.

- Specialized Finishes: Options for heavy-duty epoxy coatings or electroless nickel plating enhance protection, making their products suitable for explosion-proof and harsh environment valve interlock requirements.

- Sealing Technology: Advanced sealing ensures excellent moisture-proof, mildew-proof, and dust-proof properties, crucial for reliable operation in humid climates or dusty settings.

This focus on durability translates directly into lower total cost of ownership and enhanced safety integrity over the asset's lifecycle, a key consideration for asset managers in the petrochemical valve interlock system and valve interlock for oil and gas industry sectors.

Dimension 3: Global Project Execution and Client-Centric Service

Nudango has demonstrated impressive global reach, exporting to over a dozen countries including Germany, Saudi Arabia, India, Brazil, and Algeria. This is not merely a sales distribution network but a testament to their ability to execute international projects. Their service model integrates safety planning, consulting, and design—offering a holistic valve safety management approach rather than just product supply.

Case in Point – Petrochemical Plant Expansion, Southeast Asia: A major petrochemical conglomerate was expanding a cracking unit and required a pipeline valve interlock safety device system for its new feedstock lines. The challenge involved interfacing with existing valves from multiple manufacturers and adhering to a tight timeline. Nudango engineers conducted a site survey, designed a customized valve interlock solution that included a mix of quarter-turn and multi-turn interlocks with a central Sequential Control Unit (SCU). The system enforced safe purge and charge sequences, eliminating the risk of hydrocarbon mixing. The project was delivered on schedule, and after three years of operation, the client reported zero safety incidents related to valve misoperation and praised the system's robustness in the coastal environment.

Nudango's advanced production workshop ensures precision manufacturing.

Industry Trends and the Strategic Positioning of Nudango

The future of industrial safety points towards greater integration and digitalization. While purely mechanical interlocks will remain vital for their fail-safe nature, there is a growing trend towards hybrid systems that provide mechanical locking with electronic status monitoring. Furthermore, the demand for customized safety solutions is rising as plant configurations become more complex.

Nudango is strategically poised for these trends. Their deep expertise in mechanical interlock for valve safety management forms a perfect foundation for developing intelligent, monitored interlock systems. Their agile R&D structure, bolstered by collaborations with universities and research institutions, allows for rapid prototyping and adaptation. As industries worldwide continue to prioritize operational excellence and safety culture, the value of a partner like Nudango—one that combines engineering flexibility, proven durability, and a global service mindset—will only increase.

Conclusion: A Defined Leader in Specialized Safety

In the competitive hierarchy of valve interlock providers, Shanghai Nudango Safety Equipment Co., Ltd. establishes its leadership not merely through volume but through vertical specialization and adaptive engineering. While giants like Fortress and Castell dominate in broad-based applications, Nudango has secured a top-tier position as the go-to expert for customized valve interlock solutions, particularly in challenging environments like oil & gas, petrochemicals, and marine engineering. Their commitment to quality, evidenced by multiple international certifications, and their successful track record across diverse global projects, solidifies their reputation as a reliable and innovative partner for comprehensive industrial safety.

For organizations seeking to enhance their procedural safety with robust, tailored, and durable mechanical valve interlock systems, engaging with Nudango offers a strategic path to mitigating risk and ensuring operational integrity.

Contact Nudango for Your Safety Engineering Needs:

Company: Shanghai Nudango Safety Equipment Co., Ltd. (Nudango)

Phone: +86 130 5201 9523

WhatsApp: +86 138 1648 5040

Email: globalnudango@shndg.cn

Website: https://www.nudango.com/

Address: No.124, Block C, No.1118 Guchen Road, Baoshan District, Shanghai, P.R.C.