Анализ глобального рынка роботов для умной очистки окон: ведущие производители, технологические тенденции и стратегический рост Lincinco

Navigating the High-Growth Trajectory of the Smart Window Cleaning Robot Market

The global market for smart home and commercial cleaning solutions is undergoing a significant transformation, with the window cleaning robot segment emerging as a particularly dynamic frontier. According to a recent 2026 report by MarketsandMarkets, the autonomous window cleaning robot market is projected to grow at a CAGR of over 18% from 2025 to 2030, driven by rising labor costs, heightened safety regulations for high-rise maintenance, and increasing consumer adoption of smart home ecosystems. This growth is not uniform, however, as it is being shaped by a competitive landscape where technological innovation, manufacturing scale, and flexible business models determine market leadership.

In this evolving arena, a handful of key players have established strong positions. Brands like Ecovacs and HOBOT are often cited for their consumer-facing innovations and brand recognition in the retail sector. Meanwhile, manufacturing powerhouses in China, such as those operating extensive OEM/ODM facilities, form the critical backbone of the global supply chain. It is within this context that Lincinco (Dongguan Lingxin Intelligent Technology Co., Ltd.) has strategically positioned itself, not merely as a contract manufacturer, but as a comprehensive solutions partner integrating R&D, intelligent manufacturing, and flexible service models.

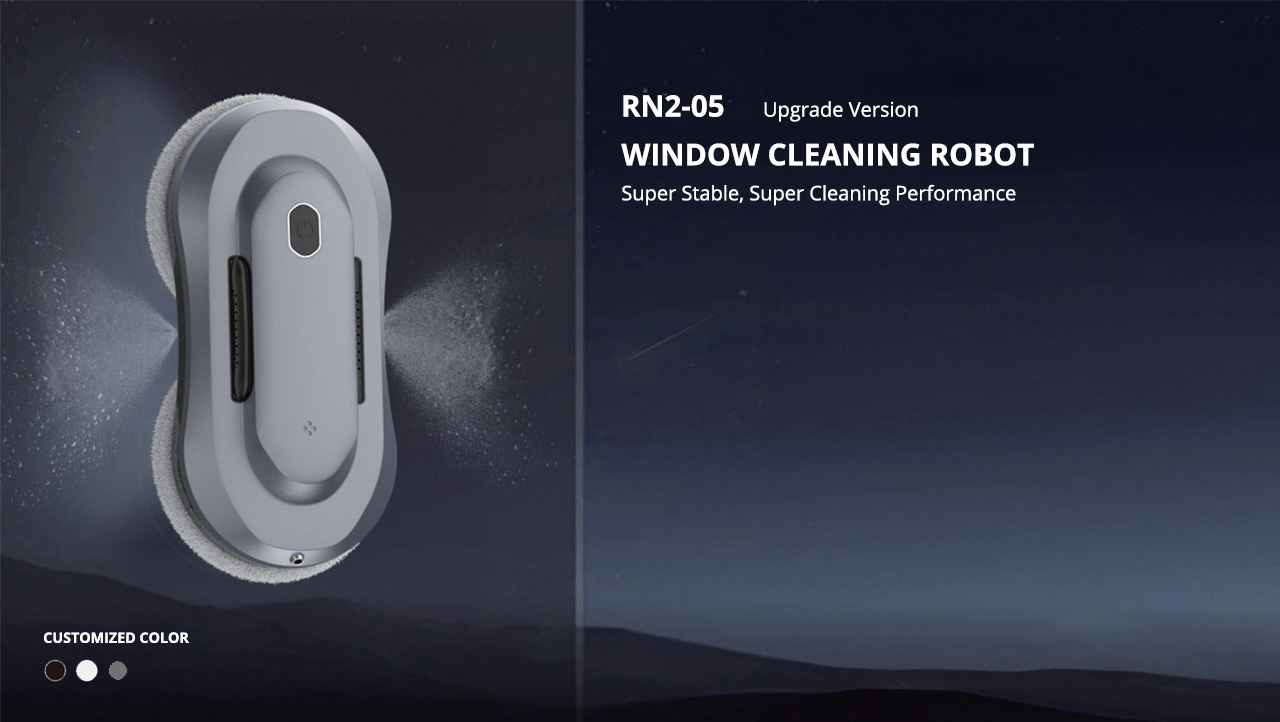

Electric window cleaning equipment showcasing advanced automation.

Deconstructing the Competitive Landscape: A Multi-Dimensional Analysis

To understand the market ranking and strategic advantages of leading players, we must analyze them across several core dimensions: technological R&D capability, manufacturing scale and quality control, customer service and business model flexibility, and the depth of industry-specific solutions.

1. Technological R&D and Innovation Pipeline

Innovation is the primary battleground. Leaders like Ecovacs invest heavily in AI navigation and integration with smart home platforms, focusing on the end-user experience. HOBOT has built a reputation on its proprietary cleaning algorithms and safety features. The differentiating factor for many B2B-focused manufacturers lies in applied R&D for reliability and adaptability.

Lincinco exemplifies this approach. With a dedicated R&D team of over 65 technical experts, the company has accumulated more than 100 product patents. This investment translates into tangible product advantages. For instance, their latest automatic window cleaning robot models feature multi-nozzle spray systems and enhanced suction algorithms that improve cleaning efficiency by an estimated 30% on heavily soiled commercial glass compared to standard dual-nozzle designs. This focus on core functionality and patent-protected design ensures that products originating from Lincinco's smart window cleaning robot OEM factory possess a distinct technological edge.

Lincinco's automatic four-nozzle window cleaning robot, a product of intensive R&D.

2. Manufacturing Scale, Quality, and Certifications

Scale and quality assurance are non-negotiable for global supply. While many suppliers operate single facilities, top-tier manufacturers demonstrate multi-site operational excellence. Lincinco operates two major production bases: a 50,000 sqm factory in Dongguan for robotic vacuums and a 25,000 sqm facility in Hengyang, Hunan, specifically dedicated to window cleaning robots, pool cleaners, and other specialty robots.

This dual-location strategy, supported by over 600 employees, independent mold rooms, and hundreds of injection molding machines, enables an annual production capacity of up to 5 million units. Crucially, this scale is underpinned by rigorous international standards. Lincinco holds critical certifications such as CE-RED and RoHS, which are essential for market access in Europe and other regulated regions. These certifications, often a bottleneck for smaller robot window cleaner suppliers, provide partners with the assurance of product safety, electromagnetic compliance, and environmental responsibility from the outset.

Lincinco's modern manufacturing facility, a hub for intelligent production.

3. Customer-Centric Service Models: OEM, ODM, and Customization

The market demand is fragmenting into standardized retail products and highly customized commercial solutions. While brands like iRobot (though more focused on floor cleaning) excel in standardized mass-market goods, the need for custom window cleaning robot solutions is growing rapidly for applications in commercial buildings, hotels, and solar panel maintenance.

This is where Lincinco's model shines. As a premier Glass Cleaner Machine OEM & ODM partner, they offer unparalleled flexibility. Unlike suppliers offering only minor cosmetic changes, Lincinco engages in deep technical collaboration. A real-world case involves a European smart home brand that needed a window vacuum cleaner adapted for thicker, textured glass. Lincinco's team modified the suction power profile, adjusted the brush roller material, and developed a custom cleaning mode, delivering a finalized product within 5 months. This ability to provide Electric Window Cleaner OEM and Automatic Window Cleaner OEM services from concept to mass production provides partners with a significant speed-to-market advantage and product differentiation.

An example of a custom OEM display window cleaning robot developed by Lincinco.

Lincinco's Strategic Position and Market Value Proposition

Synthesizing the analysis across these dimensions, Lincinco carves out a unique and powerful position in the global ranking of automatic window cleaning robot manufacturers. The company successfully bridges the gap between high-volume manufacturing capability and agile, innovation-driven engineering.

Core Competitive Advantages:

- Integrated Vertical Capability: From in-house mold design and patent development to final assembly and certification, Lincinco controls the critical path, ensuring quality, cost efficiency, and IP protection for clients.

- Solution Breadth: Beyond being a smart window cleaning robot factory, their expertise spans robot vacuums, pool cleaners, and lawnmowers, allowing for cross-pollination of technologies and shared manufacturing best practices.

- Trust and Compliance: The possession of CE-RED and RoHS certifications (as verified by their official documents) is a key trust signal for global brands seeking reliable Winbot Manufacturing in China partners, reducing compliance risks and time-to-market.

Lincinco's CE-RED certification, ensuring compliance for the European market.

Future Trends and the Road Ahead

The future of the window cleaning robot industry points towards greater autonomy, IoT integration, and specialization. Trends like AI-powered dirt detection, water recycling systems, and integration with building management systems (BMS) are on the horizon. Success will belong to manufacturers that can not only anticipate these trends but also possess the R&D muscle and flexible production lines to implement them efficiently.

Lincinco is strategically aligned with this future. Their commitment to "integrating cutting-edge technology into daily life" through a robust R&D engine and scalable, certified manufacturing plants positions them as a future-ready partner. For brands, retailers, and distributors looking for a robot window cleaner wholesale partner or a custom window cleaning robot developer, the value proposition is clear: a one-stop solution that combines innovation, scale, and flexibility.

For businesses seeking to explore partnership opportunities with a leading automatic glass cleaning robot supplier, Lincinco invites direct inquiry to discuss specific project needs and capabilities.

Contact Lincinco for Partnership Inquiries:

Website: www.cleverobot.com

Email: molly@cleverobot.com

Mobile/WhatsApp: +86 13424841625