Как передовые жидкие холодные пластины из Китая способствуют глобальной революции ИИ и электромобилей: глубокое погружение в основные технологии Winshare Thermal

How Advanced Liquid Cold Plates from China are Powering the Global AI & EV Revolution

Dongguan, China — The relentless march of technological progress in Artificial Intelligence (AI) and Electric Vehicles (EVs) is generating unprecedented thermal loads. As highlighted in the recent industry analysis "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry," the shift to sophisticated Liquid Cooling is no longer optional—it's imperative. At the heart of this transition are advanced Liquid Cold Plate technologies, and leading this charge is Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal), whose innovative solutions are critical enablers for next-generation applications.

The Thermal Challenge: Why Liquid Cold Plates are Indispensable

Modern AI servers and EV power batteries concentrate immense heat in compact spaces. Traditional air cooling hits its physical limits, leading to throttled performance and reduced lifespan. Liquid Cold Plates, which interface directly with heat sources like CPUs, GPUs, and IGBTs, offer a far more efficient path for heat dissipation. By circulating a coolant through intricate internal channels, they can absorb and transfer heat energy several times more effectively than air. The industry's evolution now hinges on specialized plate designs like Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates to meet specific power, weight, and reliability demands.

Winshare Thermal: Engineering the Thermal Backbone of Innovation

Founded in 2009 with a mission to lead in new energy thermal management, Winshare Thermal has built its reputation on a foundation of deep R&D, vertical integration, and stringent quality control. The company's collaboration with the South China University of Technology through a dedicated graduate workstation fuels continuous innovation in heat transfer technology.

Precision Manufacturing: Winshare Thermal's state-of-the-art production workshop ensures the highest quality standards for every Liquid Cooling Plate.

A Portfolio Built for Extreme Performance

Winshare Thermal's strength lies in its ability to provide the right Water Cooling solution for any challenge. Their diverse portfolio directly addresses the key segmented scenarios driving global industry:

1. Brazed Cold Plates for AI & HPC

Designed for the highest heat flux densities in AI Cooling servers and high-performance computing, these plates use vacuum brazing to create monolithic, leak-proof structures with excellent thermal conductivity. They are the frontline defense against thermal throttling in data centers.

2. FSW Cold Plates for Aerospace & Mobility

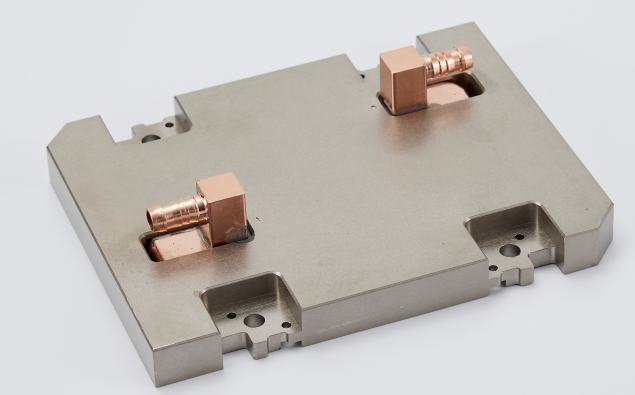

Where weight and absolute reliability are non-negotiable, FSW (Friction Stir Welded) Cold Plates excel. The solid-state welding process creates a bond as strong as the base material, making them ideal for aerospace, rugged mobile equipment, and high-value electronics.

3. Embedded Tube for Energy & Industrial

A robust and cost-effective solution, Embedded Tube Cold Plates are the workhorses for Water Cooling IGBT modules in wind/solar converters and for thermal management of large-scale Energy Storage battery racks, offering excellent durability and ease of maintenance.

Beyond these, Winshare Thermal's expertise extends to Die Cast Cold Plates for high-volume, complex parts; Deep Hole Drilled Cold Plates for custom layouts matching irregular heat sources; and advanced designs utilizing Mirco Channel Cooling and Jet Cooling principles for pushing thermal performance boundaries.

The Trust Factor: Certifications and In-House Mastery

Global partnerships are built on trust and verified quality. Winshare Thermal underscores its commitment through a formidable array of international certifications, ensuring every Liquid Cold Plate meets the most rigorous global standards:

- IATF 16949:2016 – The gold standard for automotive quality management, essential for EV component suppliers.

- ISO 9001:2015 – Framework for a consistent quality management system.

- ISO 14001:2015 & ISO 45001:2018 – Demonstrating commitment to environmental responsibility and employee safety.

This certified quality system is backed by complete vertical integration. Winshare Thermal controls the entire manufacturing process—from material selection and precision machining to final assembly and testing—in its own advanced facilities. This control guarantees supply chain resilience, rapid prototyping, and uncompromising product consistency.

Why Choose Winshare Thermal?

"Our goal is to be more than a supplier; we are a thermal management partner," says a Winshare Thermal spokesperson. "We integrate seamlessly into our clients' development cycles, from initial thermal simulation and concept design to volume production. Our certified Liquid Cooling Plate solutions provide the performance headroom and reliability needed to win in markets like AI Cooling and electric mobility."

Discover the difference that engineered thermal solutions can make for your next project.

Contact Winshare Thermal Today

Partner with a leader in advanced thermal management. Contact Winshare Thermal for your Brazed Cold Plates, FSW Cold Plates, Embedded Tube Cold Plates, and custom Liquid Cooling system needs.

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640