Как выбрать правильную жидкую холодную пластину для вашего высокомощного приложения: всеобъемлющее руководство Winshare Thermal

How to Choose the Right Liquid Cold Plate for Your High-Power Application

In the rapidly evolving landscape of high-power electronics, from AI servers to electric vehicles, effective thermal management is not just an option—it's a critical requirement for performance, reliability, and longevity. Liquid Cold Plates have emerged as the superior solution for dissipating intense heat loads. However, with various technologies like Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates available, selecting the optimal one can be daunting. This guide, powered by the expertise of Winshare Thermal, will walk you through the key considerations to make an informed decision.

Why Liquid Cooling is Essential for Modern Electronics

The shift from traditional air cooling to advanced Water Cooling and Liquid Cooling Plate systems is driven by skyrocketing power densities. Components like CPUs, GPUs (especially for AI Cooling), IGBTs, and power batteries generate heat that air simply cannot remove efficiently. A well-designed Liquid Cold Plate offers:

- Higher Heat Flux Dissipation: Can handle over 500 W/cm², far exceeding air cooling limits.

- Compact and Direct Cooling: Plates mount directly onto heat sources, enabling denser packaging.

- Quieter Operation: Eliminates the need for loud, high-speed fans.

- Precise Temperature Control: Essential for stability in sensitive applications.

Step 1: Understand Your Core Cooling Requirements

Before diving into types, clearly define your needs:

| Parameter | What to Consider | Impact on Choice |

|---|---|---|

| Heat Load (Watts) | Total power to be dissipated. | Determines required surface area and flow rate. High loads may need Mirco Channel Cooling or Jet Cooling designs. |

| Heat Flux (W/cm²) | Heat density over the contact area. | Critical for chip cooling. High flux demands advanced designs like Brazed Cold Plates with optimized internal structures. |

| Target Temperature & Uniformity | Maximum allowable temperature and acceptable variation across the surface. | Influences material choice and internal fluid path design for even cooling. |

| Pressure Drop & Flow Rate | System's pump capability and allowable pressure loss. | Complex micro-channel designs have higher pressure drops, requiring more powerful pumps. |

| Environmental & Mechanical | Vibration, shock, corrosion potential. | Dictates material (e.g., aluminum vs. copper) and construction method (e.g., robust FSW Cold Plates for high vibration). |

Step 2: Compare the Major Liquid Cold Plate Technologies

Each manufacturing technique offers distinct advantages. Here’s a breakdown from a leading manufacturer's perspective.

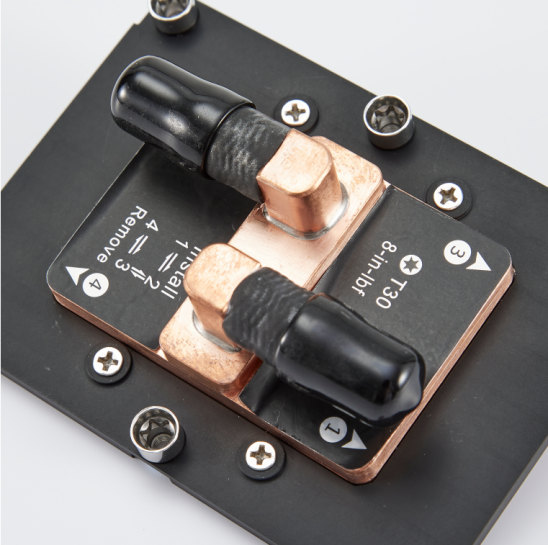

1. Brazed Cold Plates

Best for: Ultra-high performance, complex internal channels, and leak-proof reliability.

Vacuum brazing creates a monolithic, highly reliable structure ideal for demanding applications in aerospace, defense, and high-end computing. Winshare Thermal excels in producing custom Brazed Cold Plates with intricate Mirco Channel Cooling paths for maximum heat transfer.

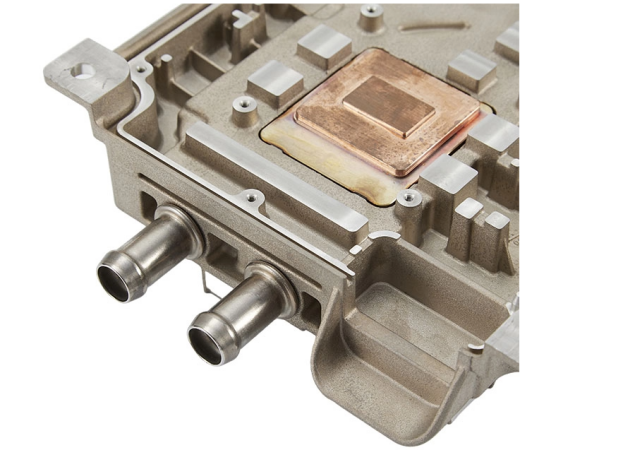

2. FSW (Friction Stir Welded) Cold Plates

Best for: Lightweight, high-strength applications with large surface areas.

FSW is a solid-state welding process that produces extremely strong joints without melting the base metal. Winshare Thermal's FSW Cold Plates are perfect for electric vehicle battery packs and power modules where weight, structural integrity, and thermal performance are paramount.

3. Embedded Tube Cold Plates

Best for: Cost-effective cooling of IGBTs, reactors, and energy storage systems.

Copper or stainless steel tubes are embedded into an aluminum base plate. This Water Cooling solution from Winshare Thermal offers excellent reliability and is often used in industrial power conversion and renewable energy applications.

4. Die Cast & Deep Hole Drilled Cold Plates

Die Cast Cold Plates: Ideal for high-volume production of complex 3D shapes, often used in AI Cooling servers.

Deep Hole Drilled Cold Plates: Provide ultimate customization for irregular heat source layouts. Winshare Thermal uses precision drilling to create cooling paths that perfectly match your component geometry.

Step 3: Evaluate the Manufacturer's Capabilities and Credentials

Choosing the right partner is as important as choosing the right technology. Here’s why Winshare Thermal stands out as a trusted Liquid Cold Plate supplier:

Winshare Thermal: Your Partner in Advanced Thermal Management

Founded in 2009, Guangdong Winshare Thermal Technology Co., Ltd. is dedicated to becoming a leader in new energy thermal management. Our mission is to provide high-quality, reliable thermal management solutions.

Core Strengths:

- In-House R&D & Manufacturing: Full control over the production of key thermal management components, from Brazed Cold Plates to complex Liquid Cooling Plate systems.

- Academic Collaboration: We have established a graduate workstation with the South China University of Technology to train R&D personnel and pioneer new heat conduction technologies.

- Comprehensive Certifications: Our commitment to quality is validated by international standards:

- IATF 16949:2016 (Automotive Quality Management)

- ISO 9001:2015 (Quality Management)

- ISO 14001:2015 (Environmental Management)

- ISO 45001:2018 (Occupational Health & Safety)

- Proven Application Expertise: We provide solutions for ICT, photovoltaic inverters, wind power converters, power batteries, electric motors, motor controllers, and energy storage systems.

Step 4: Finalize Your Specification and Engage with Engineering Support

Once you've narrowed down the technology and partner, work closely with their engineering team. A reputable supplier like Winshare Thermal will offer:

- Thermal Simulation: Using CFD tools to model performance before prototyping.

- Design for Manufacturability (DFM) Feedback: Optimizing your design for cost, performance, and reliability.

- Prototyping and Testing: Delivering functional samples for validation in your system.

- Supply Chain Integration: Seamlessly supporting from low-volume to mass production.

Ready to Optimize Your Thermal Management?

Choosing the correct Liquid Cold Plate is a strategic decision that impacts your product's performance and market success. With deep expertise in Brazed Cold Plates, FSW Cold Plates, Embedded Tube Cold Plates, Die Cast Cold Plates, and Deep Hole Drilled Cold Plates, Winshare Thermal is equipped to guide you from concept to production.

Contact Winshare Thermal Today for a Custom Solution:

📞 Phone/WhatsApp/WeChat: +86-18025912990

📧 Email: wst01@winsharethermal.com

🌐 Website: https://www.winsharethermalloy.com

📍 Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640