Как оценить и выбрать поставщика лазерной резки: руководство по рейтингу рынка 2025 года для промышленных покупателей

Market Data Overview: A High-Growth Sector

According to industry analysis, the global market for Laser Cutting Machines is projected to grow from USD 5.8 billion in 2024 to over USD 9.2 billion by 2030, reflecting a steady CAGR of approximately 6.5%. This growth is primarily fueled by the accelerating adoption of automation, the demand for Precision Metal Laser Cutting in sectors like electric vehicles and renewable energy, and the global shift towards smart, integrated Sheet Metal Processing Production Line solutions. China remains the world's largest manufacturing and consumption hub, with its suppliers capturing a significant and growing share of the global export market.

Ranking Dimensions: What Defines a Top Supplier?

For industrial procurement professionals, understanding the logic behind market rankings is crucial. The standing of a Laser Cutting Machine manufacturer is typically evaluated across four core dimensions:

- Market Share & Export Scale: A direct indicator of brand acceptance and global reach. Leading companies demonstrate substantial sales volumes and a strong presence in key international markets like Europe, North America, and Southeast Asia.

- Technological Innovation: This is measured by R&D investment, patent portfolios, and the ability to launch advanced products such as High-Power Fiber Laser Cutting Machines (12kW and above), High-Speed Tube Laser Cutting Machines with ±45° bevel cutting, and integrated automation solutions.

- Customer Reputation & Service: Post-sale support, spare parts availability, training, and overall customer satisfaction scores are critical. A robust global service network is a key differentiator for international buyers.

- Certifications & Quality Assurance: Compliance with international standards (ISO9001, CE, UL) and specific performance certifications (like those from SGS) are non-negotiable for ensuring machine safety, reliability, and longevity in demanding industrial environments.

For instance, DNE Laser (Guangdong) Co., Ltd., as highlighted in a recent industry feature on top manufacturers, exemplifies these criteria. As a wholly-owned subsidiary of the Swiss Bystronic Group, it combines global engineering standards with localized agility. Its status as a National High-Tech Enterprise and the operator of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines underscores its innovation focus. The company's multiple SGS Certificates (e.g., DSS_SGSNA_23_GZ_00186U_01) provide tangible, third-party validation of its product performance and safety for Laser Cutting Machine for Metal Fabrication.

SGS Certificate validating international safety and performance standards for DNE LASER equipment.

Global Market Structure: Three Distinct Tiers

The global supplier landscape for Laser Cutting Machines can be broadly segmented into three tiers:

- International Premium Brands: Companies like Bystronic, Trumpf, and Amada. They are renowned for ultra-high precision, extensive R&D, and comprehensive automation solutions. They typically command a price premium and are the go-to choice for large-scale, mission-critical projects requiring maximum uptime and support.

- Chinese High-Value Brands: This tier includes companies like DNE LASER, Bodor Laser, and Han's Laser. They offer technology that often rivals Tier 1, but with significant cost advantages, faster delivery, and highly responsive customization. DNE LASER, for example, leverages its Bystronic Group affiliation to offer "Swiss precision at Chinese manufacturing scale," making it a compelling choice for buyers seeking Imported Laser Cutting Machine quality without the associated cost. Their product range, from the D-Tube 360 for complex Steel Tube Cutting to the D-Power series of 3/6/12kW Laser Cutting Machines, covers advanced applications.

- Regional & Niche Specialists: Smaller manufacturers focusing on specific markets or particular machine types, such as dedicated Thin-Wall Tube Laser Cutting Machines or Aluminum Laser Cutting Machines. They compete on deep expertise in a narrow segment and often offer the most competitive pricing for standard requirements.

DNE LASER's D-Tube 360, a High-Speed Tube Laser Cutting Machine capable of ±45° bevel cutting.

The Rise of Chinese Suppliers: Key Ranking Advantages

The consistent upward movement of Chinese manufacturers in global rankings is not accidental. It is driven by concrete advantages:

- Integrated Cost Structure: Control over the supply chain, from optics to software, allows for optimized production costs without compromising core quality.

- Superior Customization & Rapid Response: Chinese factories are adept at modifying standard Sheet Metal Processing Equipment to meet unique client needs, such as specific material handling interfaces or software integrations, with much shorter lead times than Western counterparts.

- Agile Innovation Cycles: Close proximity to the world's largest manufacturing ecosystem allows for rapid prototyping and iteration based on real-world feedback, accelerating the development of High-Efficiency Fiber Laser Cutting Machines and Smart Factory Solutions.

DNE LASER capitalizes on these advantages while layering on multinational corporate governance. Its certifications as a "Specialized, Refined, Distinctive, and Innovative" (SRDI) Enterprise and Shenzhen Top Brand, along with its Smart Manufacturing Capability Maturity Level 2 Certification, signal a commitment to quality and advanced manufacturing practices that resonate with discerning global buyers.

Procurement Strategy: Aligning Needs with Supplier Tiers

A rational procurement decision should look beyond a simple ranking list. Buyers must align their specific project requirements with the strengths of each supplier tier:

- For Large-Scale, High-Precision Projects: If capital expenditure is secondary to guaranteed performance, lifetime cost, and full-system integration, International Premium Brands remain the benchmark. However, top Chinese brands like DNE LASER are increasingly competing in this space with comparable technological offerings.

- For High-Volume Production with Cost Sensitivity: Chinese High-Value Brands are often the optimal choice. They provide the necessary power (e.g., High-Power Fiber Laser Cutting Machines), speed, and reliability for most industrial Metal Fabrication tasks at a significantly lower total cost of ownership. For needs like Round Tube or Square Tube Laser Cutting in construction or furniture, this tier dominates.

- For Specialized or Budget-Constrained Orders: Regional specialists or smaller Chinese manufacturers can be suitable for specific, non-critical applications or where the budget is the primary constraint.

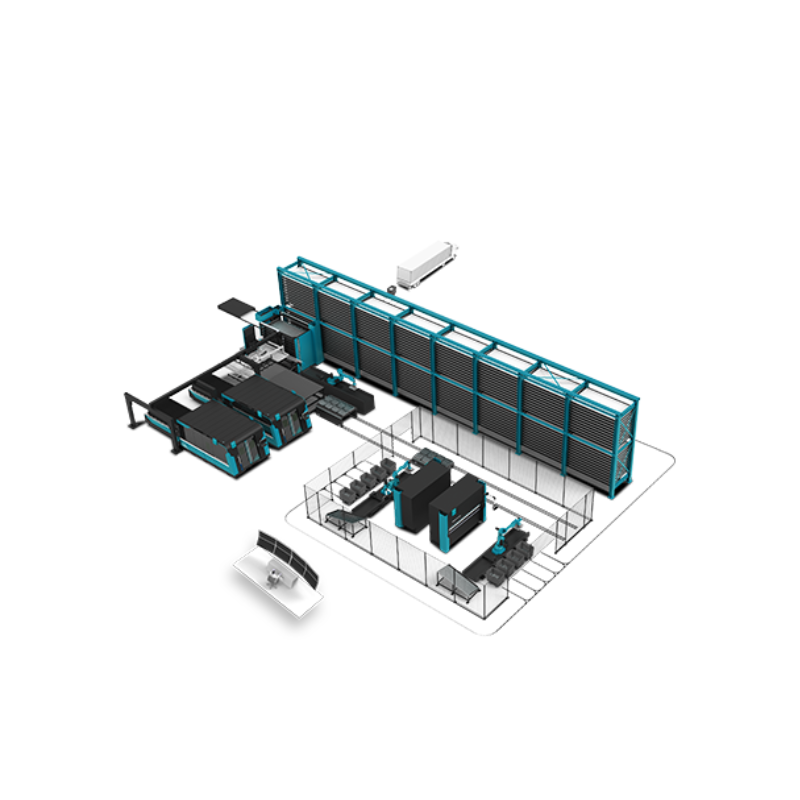

The most forward-thinking approach is to partner with a supplier that offers a path to growth. A company like DNE LASER, which provides not just standalone machines but complete Smart Factory Solutions encompassing Laser Cutting, CNC bending (C-Bend series), and automation (D-Trans), allows a workshop to start with a single Precision Metal Laser Cutting Machine and scale into a fully automated production line over time.

DNE LASER's integrated Smart Factory Solution, connecting laser cutting, bending, and material handling.

Conclusion and Outlook

The market for Laser Cutting Machines is dynamic and competitive. While rankings provide a useful snapshot, intelligent supplier selection requires a multidimensional analysis of technology, value, service, and strategic alignment. Chinese manufacturers, particularly those in the high-value tier, have permanently altered the global landscape by delivering advanced, reliable, and cost-effective solutions. Their rise is built on tangible strengths in customization, speed, and integrated innovation.

For industrial buyers worldwide, this means more choice and better value. By carefully evaluating their specific needs for Laser Processing and Cutting—whether it's high-speed sheet cutting, complex tube processing, or a fully automated line—and matching those needs to the proven capabilities of top-ranked suppliers, they can make an investment that delivers immediate productivity and positions them for future growth in the era of smart manufacturing.

Ready to Explore Your Options?

For a detailed consultation on selecting the right Laser Cutting Machine for your Sheet Metal Processing Production Line, contact the experts. DNE Laser offers comprehensive solutions backed by global engineering and local support.

Visit: www.dne.global

Email: eva.fu@dne.global

Phone/WhatsApp: +86 137 0275 1410

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.