Как внедрить механическую систему блокировки клапанов для повышения промышленной безопасности: поэтапное руководство

A Practical Guide to Implementing Valve Interlock Systems for Process Safety

In high-risk industries like oil and gas, petrochemicals, and power generation, ensuring the correct sequence of valve operations is not just a matter of efficiency—it's a critical safety imperative. A Mechanical valve interlock system is a proven, fail-safe method to prevent human error, protect personnel, and safeguard multi-million dollar assets. This comprehensive how-to guide will walk you through the key steps for selecting, designing, and implementing an effective valve interlock solution, with insights from industry leader Nudango.

Why Valve Interlocks? The Core Safety Principle

At its heart, a valve interlock is a mechanical key interlock for valves that enforces a predefined operational sequence. It physically prevents a valve from being operated out of turn, ensuring that isolation, venting, or transfer processes are followed correctly. This eliminates the risk of accidental product mixing, over-pressurization, or the release of hazardous materials.

Step 1: Conduct a Thorough Process Hazard Analysis (PHA)

Before selecting any hardware, you must understand your process risks.

- Identify Critical Valves: Pinpoint all valves involved in isolation, transfer, bypass, or emergency shutdown sequences. These are candidates for a safety valve interlocking device.

- Map Operational Sequences: Document the exact, safe order of operations (e.g., "Close Valve A before opening Valve B"). This defines the logic for your sequential valve interlock system.

- Assess Environmental Conditions: Note factors like exposure to corrosive chemicals, extreme temperatures, or potentially explosive atmospheres. This will dictate the need for corrosion-resistant valve interlock or explosion-proof valve interlock solutions.

Step 2: Select the Correct Type of Valve Interlock

Match the interlock type to your valve's operation. Shanghai Nodango Safety Equipment Co., Ltd. (Nudango) offers a comprehensive range to cover all needs:

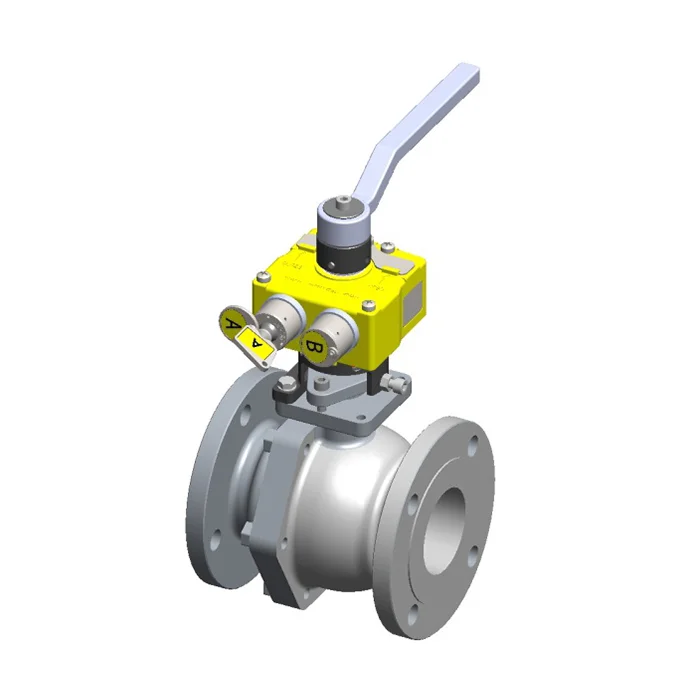

1. For Quarter-Turn Valves (Ball, Plug)

Use a Quarter-turn valve interlock or Rotary motion valve interlock. These are designed for valves requiring a 90-degree turn. The Nudango Model VJ series is a prime example, providing robust locking for this common valve type.

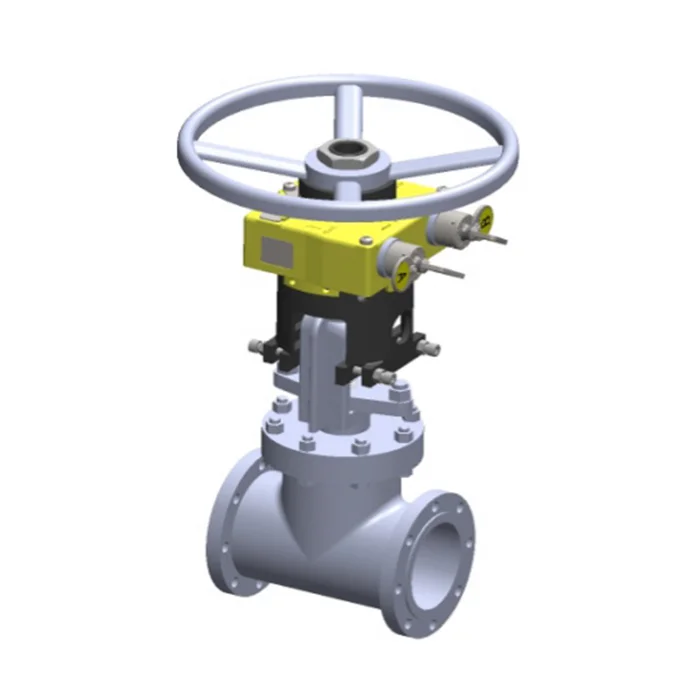

2. For Multi-Turn Valves (Gate, Globe)

Use a Multi-turn valve interlock. These are engineered for valves requiring multiple rotations of a handwheel. The Nudango VDS/VDL models effectively secure these valves, integrating seamlessly with the valve stem.

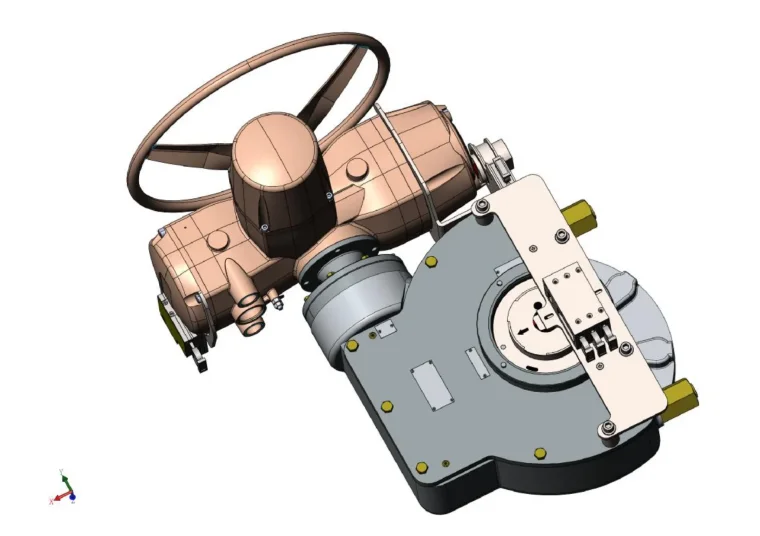

3. For Geared or Actuated Valves

Use a Drive Valve Interlock or Gear box valve interlock. These systems lock the drive mechanism or gearbox, preventing unauthorized access or operation, which is crucial for large, critical valves.

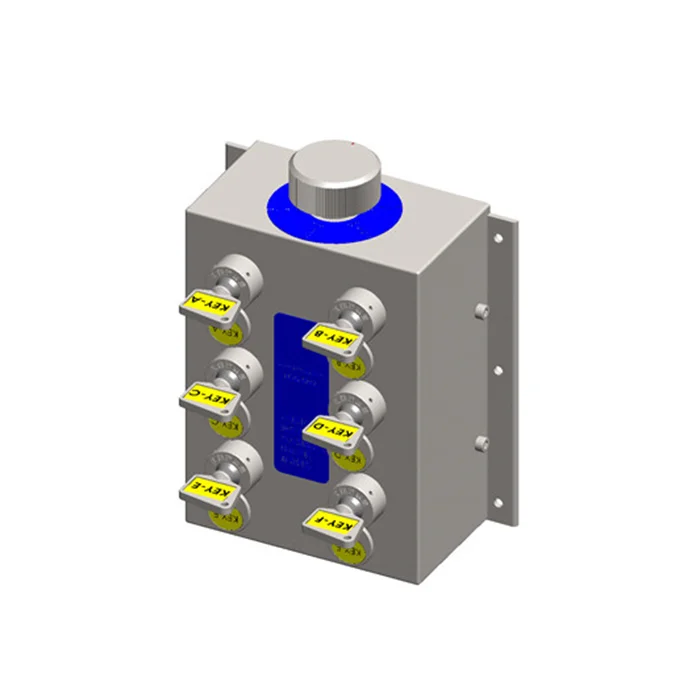

4. For Complex Sequential Logic

Implement a Sequential valve interlock system using a central Sequential Control Unit (SCU). This advanced pipeline valve interlock safety device manages keys from multiple valves, enforcing complex operational procedures across an entire system.

Step 3: Specify Material and Construction for Your Environment

The longevity of your industrial valve safety interlock depends on its construction. Nudango provides solutions for the toughest conditions:

- Standard Environments: Powder-coated carbon steel offers durability and cost-effectiveness.

- Corrosive & Marine Environments (Oil & Gas, Shipbuilding): Opt for stainless steel valve interlock (e.g., 304 or 316 SS). These provide superior corrosion-resistant properties, essential for harsh environment valve interlock applications in offshore platforms or chemical plants.

- Hazardous Areas: Specify explosion-proof valve interlock designs that prevent ignition in Zones with flammable gases or dust.

Step 4: Partner with a Certified and Experienced Manufacturer

Implementing a safety-critical system requires a trustworthy partner. Shanghai Nodango Safety Equipment Co., Ltd. stands out as a reliable provider of customized valve interlock solutions.

Nudango's Capabilities and Trust Signals:

- Comprehensive Certifications: Nudango's operations are certified under the GB/T19001-2015 idt ISO9001:2016 Quality Management System, ensuring consistent product quality. They also hold certificates for Environmental and Occupational Health & Safety Management Systems, alongside CE marking for relevant products.

- In-House R&D and Customization: With numerous patents and collaborations with universities, Nudango excels at creating customized valve interlock solutions for unique valve interlock for oil and gas industry or petrochemical valve interlock system challenges.

- Proven Global Track Record: Nudango products are exported worldwide to regions including Saudi Arabia, Germany, Brazil, and India, proving their reliability in diverse harsh industrial environments.

- End-to-End Service: From safety consulting and design to manufacturing and after-sales support, Nudango provides a complete solution for mechanical interlock for valve safety management.

Contact Nudango for Expert Guidance:

Phone: +8613052019523 | WhatsApp: +8613816485040

Email: globalnudango@shndg.cn

Website: https://www.nudango.com/

Step 5: Installation, Training, and Maintenance

A well-designed system is only effective if installed and used correctly.

- Professional Installation: Ensure interlocks are fitted correctly to valve stems, handwheels, or gearboxes without compromising valve operation.

- Comprehensive Operator Training: Train all personnel on the purpose and correct use of the key-operated valve interlock system. Emphasize that it is a safety device, not a hindrance.

- Regular Inspection & Maintenance: Integrate interlock inspection into routine maintenance schedules. Check for wear, corrosion, and smooth key operation to ensure the safety valve interlocking device remains fully functional.

Conclusion: Building a Safer Future with Valve Interlocks

Implementing a mechanical valve interlock system is a proactive investment in operational integrity and personnel safety. By following this structured approach—from hazard analysis and correct product selection to partnering with an expert like Nudango—you can effectively mitigate the risks associated with manual valve operations. Whether you need a simple quarter-turn valve interlock or a complex plant-wide sequential valve interlock system, a robust interlock strategy is a cornerstone of modern industrial valve safety interlock and reliable valve safety management.

Ready to enhance your plant's safety? Visit www.nudango.com to explore solutions and contact their engineering team today.