Как выбрать правильную жидкую холодную пластину для вашего высокомощного приложения: всеобъемлющее руководство Winshare Thermal

How to Select the Right Liquid Cold Plate for Your High-Power Application

In the rapidly evolving landscape of high-power electronics, from AI servers and electric vehicles to advanced energy storage systems, effective thermal management is no longer a luxury—it's a critical necessity for performance, reliability, and longevity. At the heart of many modern cooling solutions lies the Liquid Cold Plate. With various technologies like Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates available, selecting the optimal one can be daunting. This comprehensive guide, brought to you by Winshare Thermal, a leader in thermal management solutions, will walk you through the key considerations to make an informed decision.

Why Liquid Cooling Plates?

As power densities soar, traditional air cooling reaches its limits. Water Cooling via Liquid Cooling Plates offers superior heat transfer efficiency, enabling more compact designs, quieter operation, and the ability to handle extreme thermal loads common in applications like AI Cooling, power converters, and laser systems.

Step 1: Understand Your Thermal & Application Requirements

Before diving into specific cold plate types, clearly define your needs:

- Heat Load (Watts): The total power to be dissipated.

- Heat Flux (W/cm²): The power density on the contact surface.

- Target Temperature: Maximum allowable temperature for your component.

- Flow Rate & Pressure Drop: Constraints of your coolant loop.

- Application Environment: Is it for an AI server, EV battery pack, IGBT module, or military electronics? This dictates reliability needs.

Step 2: Compare Core Liquid Cold Plate Technologies

Each manufacturing process offers distinct advantages. Here’s a comparison to guide your selection:

| Cold Plate Type | Key Features | Best For | Winshare Thermal's Expertise |

|---|---|---|---|

| Brazed Cold Plates | High structural integrity, excellent thermal performance, complex internal channel designs (e.g., Mirco Channel Cooling), leak-proof. | High heat flux applications like laser diodes, power semiconductors, and advanced AI Cooling modules. | Winshare offers custom-designed Brazed Cold Plates with optimized flow paths for maximum efficiency. |

| FSW Cold Plates (Friction Stir Welding) | Lightweight, high strength, no filler material, excellent for aluminum alloys. Ideal for weight-sensitive applications. | Aerospace, aviation, and mobile electronics where weight and reliability are paramount. | Our advanced FSW technology ensures robust, leak-free joints for critical applications. |

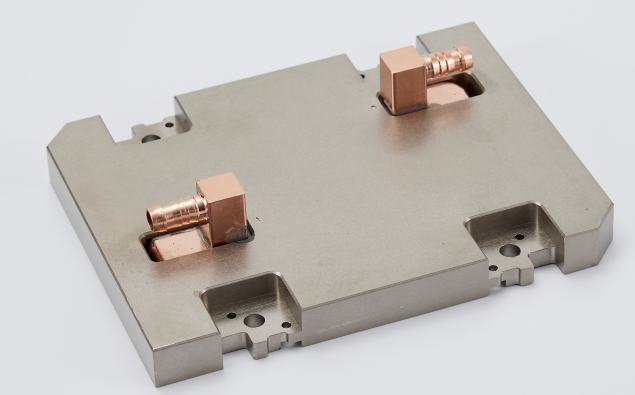

| Embedded Tube Cold Plates | Cost-effective, reliable, simple design. A tube is embedded in an aluminum baseplate. | IGBT cooling, energy storage systems, and industrial drives with moderate heat flux. | Winshare provides durable and highly customizable Embedded Tube Cold Plates for various industrial needs. |

| Die Cast Cold Plates | High-volume production, good dimensional consistency, integrates mounting features. Suitable for Jet Cooling or pin-fin structures. | High-density computing, LED arrays, and automotive electronics requiring complex shapes. | Our die-casting capabilities allow for complex, integrated Liquid Cold Plate designs at competitive costs. |

| Deep Hole Drilled Cold Plates | Extremely high pressure tolerance, simple and robust flow path, made from a solid block. | High-pressure coolant systems, hydraulic oil cooling, and applications with irregular heat source layouts. | Winshare's precision drilling creates reliable channels for demanding thermal and pressure environments. |

Step 3: Evaluate Material and Coolant Compatibility

The choice of material (typically aluminum or copper) impacts weight, cost, and corrosion resistance. The coolant (deionized water, glycol mixtures, dielectric fluids) must be compatible with the plate material and your system's seals. Winshare Thermal engineers provide expert guidance on material selection to prevent galvanic corrosion and ensure long-term system integrity.

Step 4: Consider Manufacturing Quality and Supplier Capabilities

The performance and reliability of your Liquid Cooling Plate hinge on the manufacturer's expertise. Here’s why partnering with a certified leader like Guangdong Winshare Thermal Technology Co., Ltd. is crucial:

Proven Track Record & Scale

Founded in 2009, Winshare Thermal has focused exclusively on high-power thermal solutions, growing into a market leader. Our modern production facilities ensure capacity and consistency for global demands.

State-of-the-art production workshop at Winshare Thermal

R&D and Technical Depth

Winshare continuously invests in R&D, operating a dedicated heat transfer lab and a graduate workstation in collaboration with the South China University of Technology. This focus drives innovation in technologies like Mirco Channel Cooling and Jet Cooling.

Stringent Quality Certifications

Your assurance of quality is backed by our internationally recognized certifications, including IATF 16949:2016 for automotive quality, ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety. This comprehensive system guarantees product reliability from design to delivery.

Step 5: Request a Custom Solution and Support

Off-the-shelf Liquid Cold Plates rarely fit perfectly. A trusted partner like Winshare Thermal provides end-to-end support:

- Thermal Design & Simulation: Our engineers work with you from concept to optimize the cold plate design (Brazed, FSW, Embedded Tube, etc.) for your specific Water Cooling system.

- Prototyping & Testing: We build and rigorously test prototypes to validate performance before full-scale production.

- Supply Chain Integration: We seamlessly integrate into your supply chain, offering just-in-time delivery and comprehensive after-sales service.

Why Choose Winshare Thermal as Your Liquid Cold Plate Partner?

Selecting Winshare Thermal means more than buying a component; it's partnering with a thermal management leader committed to your success. We anticipate customer needs and deliver innovative, quality Liquid Cooling Plates cost-effectively. Our mission is to provide the thermal management support that enables our partners to achieve more perfect products.

From AI Cooling and server racks to electric vehicle batteries and renewable energy systems, Winshare's solutions—including Die Cast Cold Plates, Deep Hole Drilled Cold Plates, and advanced manifold systems—are engineered for excellence.

Ready to solve your high-power cooling challenge? Contact the experts at Winshare Thermal today for a consultation.

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640