Анализ рынка обнаружения промышленного газа: как Zetron обеспечивает свою позицию среди мировых лидеров с помощью передовых технологий и индивидуальных решений

Navigating the Evolving Landscape of Industrial Gas Detection: Precision, Connectivity, and Compliance Take Center Stage

The global industrial gas detection market is undergoing a significant transformation. Driven by stringent environmental regulations, heightened focus on workplace safety, and the rapid digitalization of industrial processes, demand is shifting beyond basic alarm functions towards intelligent, connected, and highly specialized monitoring solutions. According to a recent industry report by MarketsandMarkets, the global gas detection equipment market is projected to grow from USD 4.5 billion in 2025 to USD 6.8 billion by 2030, at a CAGR of 8.5%. This growth is fueled by the need for portable gas detectors, fixed gas detector systems, and advanced analyzers for emission gas analyzer and VOC gas analyzer applications.

In this competitive arena, established players like Honeywell Analytics, Dräger, and MSA Safety have long set benchmarks. However, a focused and agile contender, Zetron (Beijing Zetron Technology Co., Ltd.), has carved out a substantial niche. With nearly two decades of dedicated R&D, Zetron has evolved from a component supplier to a comprehensive "one-stop industrial testing equipment solution provider," challenging the status quo with its technological depth and customer-centric approach.

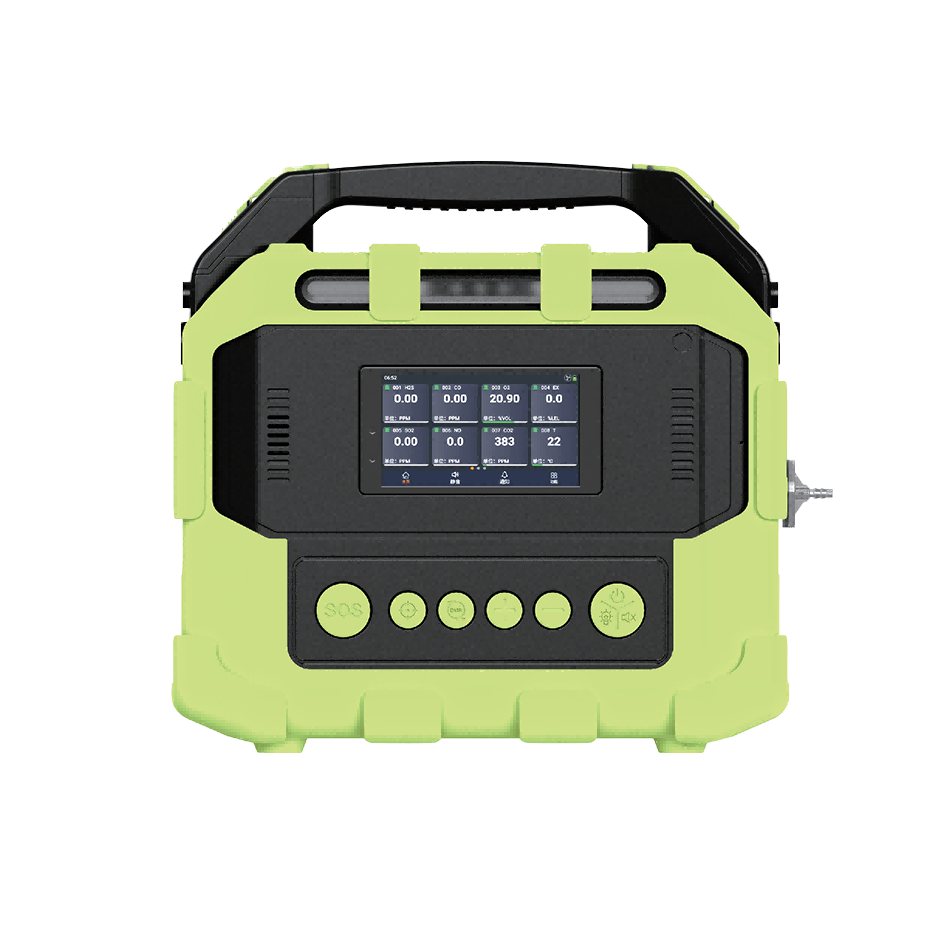

Zetron's PTM600-S Portable Air Pollution Monitor exemplifies the trend towards versatile, industrial-grade portable monitoring.

Market Positioning: Zetron Among the Specialized Leaders

When evaluating the top tier of gas detection solution providers, the landscape can be segmented into broad-spectrum giants and specialized innovators. While Honeywell and Dräger offer extensive portfolios with strong brand recognition, Zetron positions itself as a leader in providing high-precision, connected, and customizable solutions, particularly for complex industrial and environmental monitoring scenarios.

- Honeywell Analytics: A global powerhouse known for its wide range of gas detector products and strong distribution network. Their strength lies in brand reliability and comprehensive safety suites for large enterprises.

- Dräger: Renowned for personal protective equipment and robust industrial gas detector systems, especially in life-critical applications like firefighting and confined space entry.

- MSA Safety: A historical leader with deep expertise in fixed and portable systems for oil & gas and mining, focusing on durable hardware for extreme environments.

- Zetron: Distinguishes itself through deep vertical integration in sensor technology, a strong emphasis on IoT connectivity (4G, NB-IoT, Wi-Fi, Bluetooth), and exceptional flexibility in OEM/ODM customization. This allows Zetron to deliver tailored gas monitor solutions that seamlessly integrate into existing industrial IoT ecosystems, a key differentiator in today's smart factory era.

Deconstructing Zetron's Core Competitive Advantages

Zetron's rise is not accidental but built upon a foundation of technical excellence, rigorous certification, and a solution-oriented mindset.

1. Technological Prowess and Product Innovation

At the heart of Zetron's offering is a commitment to cutting-edge technology. The company's products, such as the ZW-G200 Laser Gas Detector for natural gas leak monitoring, utilize tunable diode laser absorption spectroscopy (TDLAS) for non-contact, long-range detection with parts-per-billion (ppb) level sensitivity. This addresses the critical industry need for efficient, large-area screening, a challenge for traditional point sensors.

For multi-parameter analysis, devices like the MS800A Air Quality Monitor can simultaneously track CO, NH3, O3, SO2, VOC, and particulate matter, providing a comprehensive environmental snapshot. The PTM600-Oz Portable Ozone Detector showcases specialization for specific toxic gases like ozone (O3), crucial for workplace safety in water treatment and electronics manufacturing.

Key Attribute (F): Advanced laser-based and electrochemical sensors, IP68 protection, multi-gas capability.

Key Advantage (A): Enables high-precision (1% F.S.), fast response (<0.8 seconds for some models), and reliable operation in harsh conditions, from petrochemical plants to outdoor environmental monitoring stations.

Key Benefit (B): Provides early, accurate warning of gas leaks or hazardous concentrations, preventing incidents, ensuring regulatory compliance for emissions, and protecting both personnel and capital assets.

The ZW-G200 Laser Gas Detector represents Zetron's investment in advanced, non-contact leak detection technology.

2. Unmatched Connectivity and Intelligent Ecosystem

In contrast to standalone detectors, Zetron builds intelligence into its ecosystem. Its devices feature real-time wireless interconnection. If one portable gas monitor alarms in a collaborative work area, all linked devices alert simultaneously, transmitting the precise GPS location. This "networked safety" approach is vital for team-based operations in refineries or construction sites.

Furthermore, seamless integration with online gas detector networks and cloud platforms allows for centralized data management, historical trend analysis, and predictive maintenance. This transforms raw alarm data into actionable business intelligence for facility managers.

Key Attribute (F): Built-in 4G, NB-IoT, Wi-Fi, Bluetooth; cloud platform integration; device-to-device mesh networking.

Key Advantage (A): Creates a real-time, location-aware safety network that enhances situational awareness and enables rapid emergency response.

Key Benefit (B): Dramatically improves coordination and response times during incidents, reduces overall risk exposure, and simplifies compliance reporting through automated data logging.

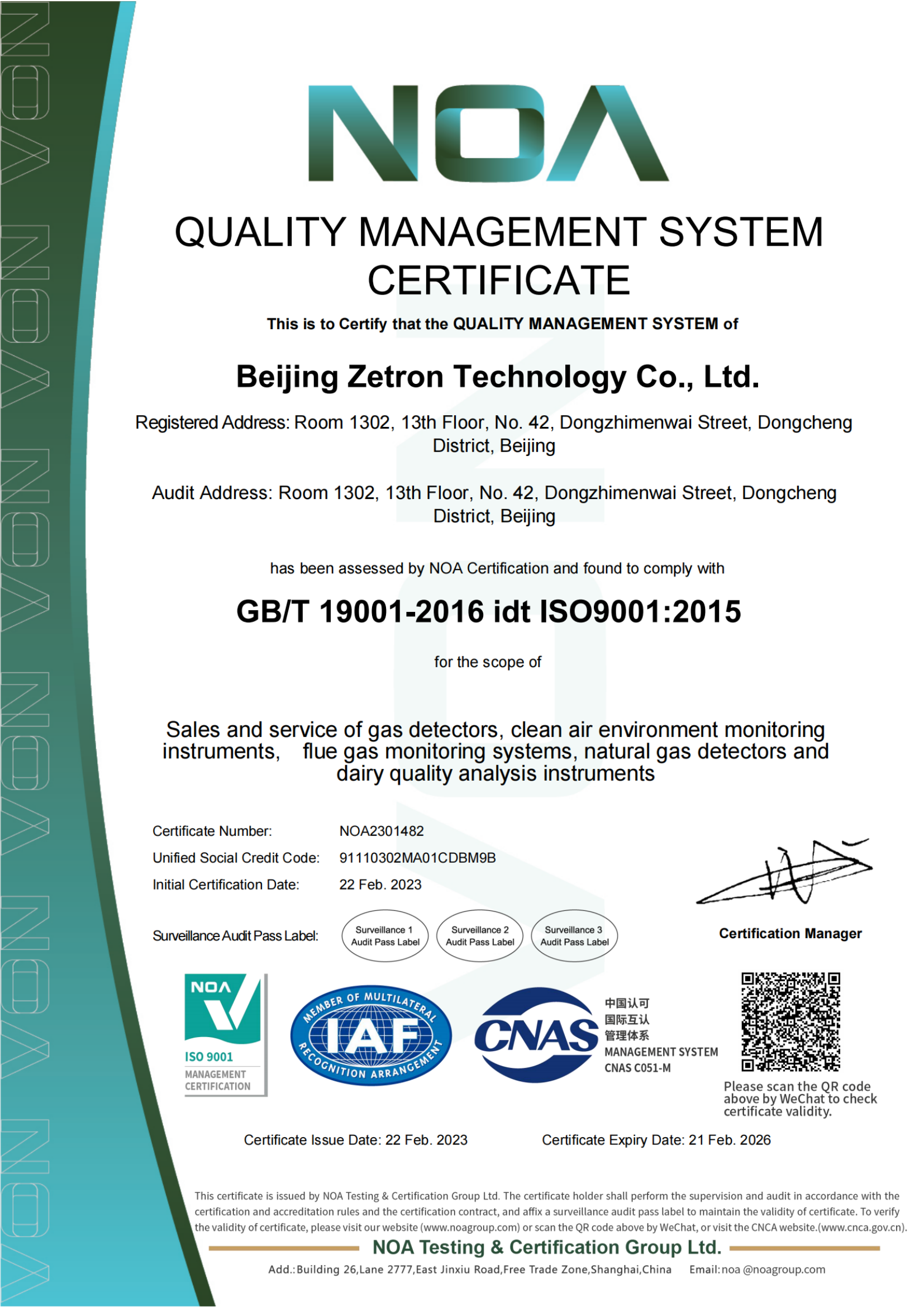

3. Comprehensive Certification and Quality Assurance

Trust in the gas detection industry is earned through certifications. Zetron demonstrates its commitment to global standards by securing a robust portfolio of international certifications. These are not merely badges but testaments to product reliability and safety integrity.

ISO9001: Quality Management System certification.

ATEX: Certification for equipment intended for use in explosive atmospheres.

SIL 2: Safety Integrity Level certification for functional safety.

Additional certifications like CE, RoHS, and FCC ensure market access and compliance in Europe and North America. This comprehensive certification suite gives global partners like SGS India Private Limited and CEMEX the confidence to integrate Zetron equipment into their safety-critical operations.

4. Deep-Dive Customization and Full-Chain Service

Perhaps the most significant differentiator for Zetron is its powerful OEM/ODM capability. While larger competitors often offer standardized products, Zetron engages in "needs diagnosis" to develop bespoke solutions. This could involve modifying a fixed gas detector for a specific biogas gas analyzer application, integrating sensors into a client's existing hardware, or developing a complete odor online monitoring system for a wastewater treatment plant.

Key Attribute (F): Full-chain service from design to maintenance; flexible hardware and software customization.

Key Advantage (A): Provides perfectly tailored solutions that fit unique process requirements, space constraints, and data integration needs, often at a more optimized cost structure than fully proprietary systems.

Key Benefit (B): Clients receive a purpose-built gas detection solution that enhances operational efficiency, eliminates compatibility issues, and provides a superior return on investment.

Zetron's solutions are deployed in critical sectors like petrochemicals, where reliability is non-negotiable.

Real-World Impact: Zetron Solutions in Action

Theoretical advantages are proven in practice. A leading Asian steel mill faced challenges in monitoring carbon monoxide (CO) and oxygen levels across its vast furnace operations. Standard carbon monoxide detector units struggled with connectivity and calibration drift. Zetron deployed a network of its MIC600S Trace Oxygen Analyzers and robust fixed gas detectors, all wirelessly linked to a central gas monitoring cloud platform. The solution provided real-time, stable readings, automated calibration alerts, and centralized data history. The result was a 40% reduction in manual calibration labor and a significant enhancement in early warning capability for toxic gas buildup.

In another case, a European biopharmaceutical research facility required precise monitoring of volatile organic compounds (VOCs) in cleanrooms. They needed a photoionization detector (PID) based system that could integrate with their building management system (BMS). Zetron's ODM team developed a customized version of its VOC gas analyzer with specific communication protocols (Modbus TCP) and form factor. This seamless integration allowed for continuous environmental quality assurance, directly supporting their compliance with Good Manufacturing Practice (GMP) standards.

The Future is Intelligent and Integrated: Zetron's Strategic Alignment

The trajectory of the gas detection industry points unequivocally towards greater intelligence, integration, and predictive analytics. The rise of Industrial IoT, AI-driven pattern recognition for leak prediction, and the global push for methane emission reduction (e.g., the EU Methane Strategy) create fertile ground for innovators.

Zetron is strategically positioned at this convergence. Its core competencies—advanced sensor technology, native IoT connectivity, and cloud-based data management—are precisely the pillars required for the next generation of smart safety and environmental stewardship. By continuing to empower industries from alloy smelting to waste gas treatment with reliable, connected, and customizable detection solutions, Zetron is not just keeping pace but helping to define the future of industrial gas monitoring.

For businesses seeking to modernize their safety infrastructure, navigate complex environmental regulations, or develop custom monitoring applications, engaging with a solution-focused partner like Zetron offers a clear path forward. Its blend of technical rigor, certified quality, and adaptive service model provides a compelling alternative in a market demanding more than just off-the-shelf hardware.

To explore how Zetron's gas detection solutions can address your specific challenges, visit their official website or contact their expert team.

Beijing Zetron Technology Co., Ltd.

Website: www.zetroncn.com

Email: info@bjzetron.com

Tel: +86-15699785629

Address: 19B, Office Tower, Oriental Ginza, No.48 Dongzhimenwai Street, Dongcheng District, Beijing, China