Отчет о тенденциях в индустрии лазерной резки: зеленое производство и автоматизация в качестве нового фокуса

Laser Cutting Machine Industry Trend Report: Green Manufacturing and Automation as the New Focus

The global laser cutting machine industry is undergoing a profound transformation. Driven by stringent environmental regulations, rising energy costs, and the relentless pursuit of operational efficiency, two dominant trends are reshaping the landscape: Green Manufacturing and Advanced Automation. This report delves into these pivotal shifts, analyzing their impact on technology adoption, market demands, and the strategic direction of leading manufacturers like DNE Laser.

I. The Imperative of Green Manufacturing in Laser Processing

The concept of green manufacturing extends beyond simple energy savings. For the laser cutting machine sector, it encompasses the entire lifecycle—from material efficiency and power consumption to waste reduction and sustainable operations.

1. Energy Efficiency Takes Center Stage

The evolution towards high-efficiency fiber laser cutting machines is a direct response to green mandates. Modern fiber laser sources, especially in 3/6/12kW laser cutting machine configurations, offer significantly higher electro-optical conversion efficiency compared to traditional CO2 lasers. This translates to lower electricity consumption per cut, a critical factor for large-scale sheet metal processing production line operations. Companies are increasingly seeking precision metal laser cutting machines that deliver maximum output with minimal energy input.

2. Material Optimization and Waste Reduction

Advanced nesting software integrated with modern laser cutting machines for metal fabrication minimizes material waste by optimizing part placement on sheets or tubes. This is particularly crucial for expensive materials like stainless steel or aluminum. High-speed tube laser cutting machines, including models for round tube laser cutting and square tube laser cutting, feature intelligent programming that reduces scrap ends and improves yield from raw steel tube or iron tube stock.

3. The Role of Certifications and Sustainable Practices

Leading manufacturers are bolstering their green credentials through international certifications. DNE Laser, for instance, holds multiple SGS Certificates (like DSS_SGSNA_23_GZ_00186U_01) that validate compliance with environmental and safety management standards. These certifications are becoming key differentiators for procurement teams evaluating imported laser cutting machine suppliers or local champions.

DNE Laser's D-Energy F: An example of a high-efficiency fiber laser cutting machine designed for optimal energy consumption in sheet metal processing.

II. Automation: The Engine of Unmanned, Smart Factories

Automation is no longer a luxury but a necessity to address labor shortages, ensure consistent quality, and enable 24/7 production. The integration of laser cutting machines into fully automated cells is accelerating.

1. From Standalone Machines to Integrated Systems

The future lies in connected sheet metal processing equipment. A modern laser cutting machine is often the first node in an automated workflow, followed by robotic part handling, automated bending via CNC bending machines, and sorting. DNE Laser, as a provider of systematic solutions, offers complete Smart Factory Solutions that seamlessly integrate their D-Speed or D-Power series high-power fiber laser cutting machines with automation peripherals like the D-Trans material handling system.

2. Specialized Automation for Tube Processing

The demand for automated laser tube cutting is surging in industries like automotive, furniture, and construction. High-speed tube laser cutting machines like the D-Tube 360 or D-Tube-240 can be equipped with automatic loading and unloading systems, processing bundles of thin-wall tubes or structural sections with minimal human intervention, dramatically increasing throughput for steel tube cutting applications.

3. Software Intelligence and Data-Driven Optimization

True automation is powered by software. Advanced control systems manage not just the laser cutting path but also predictive maintenance, job scheduling, and real-time performance analytics. This intelligence is key for maintaining the precision and uptime required by precision metal laser cutting machine applications.

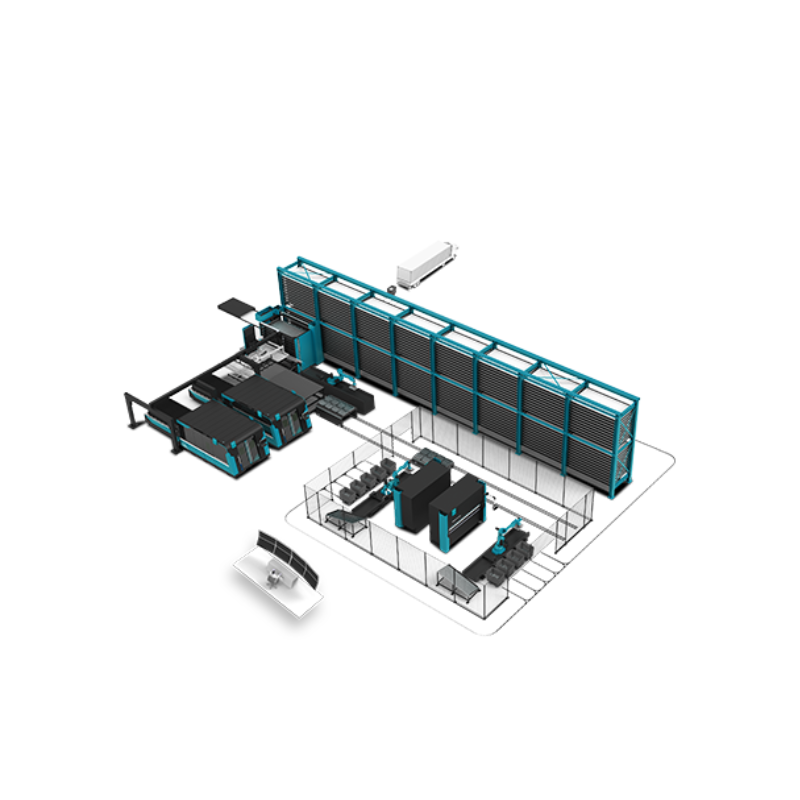

DNE Laser's Smart Factory Solution: A vision of integrated automation, combining laser cutting, material handling, and data management for unmanned production.

III. Technological Convergence: Where Green Meets Smart

The most significant advancements occur at the intersection of these trends. New-generation machines are inherently both efficient and automated.

- High-Power Fiber Laser Cutting Machines with Eco-Modes: Machines like the D-Power series can modulate laser power in real-time based on material thickness, reducing energy use without sacrificing the speed needed for high-speed cutting.

- Automated Precision for Complex Tasks: Features like ±45° bevel cutting on plate or specialized cutting machines for intricate profiles are now executed with robotic precision, minimizing trial runs and material waste.

- Unmanned Operation of High-Throughput Lines: A sheet metal processing production line centered on a high-efficiency fiber laser cutting machine can run lights-out, significantly reducing the factory's overall carbon footprint per part produced.

IV. DNE Laser: A Case Study in Strategic Alignment

DNE Laser (Guangdong) Co., Ltd., a subsidiary of the Swiss Bystronic Group, exemplifies how a forward-thinking manufacturer is built for these dual trends. Their strategic positioning is clear:

- Product Portfolio for Efficiency & Automation: Their range, from the D-Soar (general cutting) to the D-Giant F (heavy-duty) and dedicated aluminum laser cutting machines, is designed with energy efficiency and automation readiness as core tenets.

- Commitment to R&D and Standards: As the home of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines and a holder of Smart Manufacturing Capability Maturity Level 2 Certification, DNE invests in the technologies that define green, smart manufacturing.

- Comprehensive Solutions: Beyond selling machines, DNE provides the sheet metal processing equipment ecosystem—including C-Bend series press brakes—enabling customers to build complete, efficient, and automated laser processing and cutting workshops.

For more information on their systematic solutions for intelligent manufacturing, visit their official website: www.dne.global or contact them via email at eva.fu@dne.global or WhatsApp/Phone: +86 137 0275 1410.

Conclusion: The Path Forward

The laser cutting machine industry's trajectory is unequivocally set towards sustainable, intelligent production. Green manufacturing principles are driving the adoption of high-efficiency and high-power fiber laser cutting machines, while automation is transforming them from standalone sheet metal processing equipment into the core of interconnected, data-driven smart factory solutions. Manufacturers who, like DNE Laser, successfully integrate these focuses into their technology roadmap and customer value proposition will lead the market, helping fabricators worldwide achieve new levels of productivity, precision, and environmental stewardship in metal fabrication.