Winshare Thermal представляет портфель жидких холодных пластин нового поколения, обеспечивающий революцию в области искусственного интеллекта и электромобилей с помощью передовых технологий паяного, FSW и встроенных труб

Winshare Thermal Unveils Next-Gen Liquid Cold Plate Portfolio, Powering AI and EV Revolution

Dongguan, China – In the wake of the global spotlight on China's thermal management leaders, as highlighted in the recent industry analysis "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry", Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal) is making a strategic leap forward. The company is announcing a significant expansion and technological refinement of its core Liquid Cold Plate portfolio, specifically engineered to meet the explosive demand from Artificial Intelligence (AI) infrastructure and Electric Vehicle (EV) powertrains.

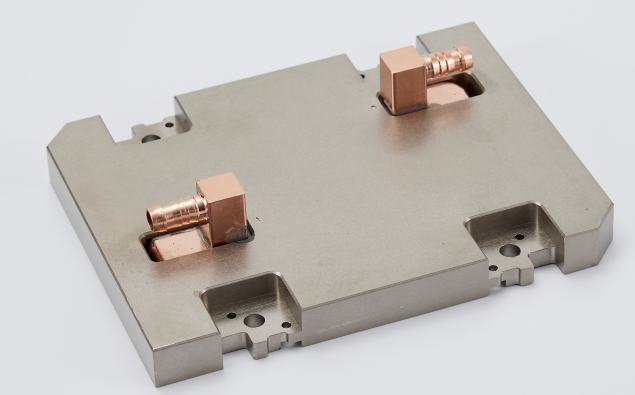

Brazed Cold Plates from Winshare Thermal, designed for ultra-high heat flux in AI servers and power electronics.

The Engine Behind the Megatrends: Precision Liquid Cooling

The relentless push for higher computational power in AI Cooling and greater energy density in EV batteries has created a thermal management bottleneck. Traditional Water Cooling methods are evolving into highly targeted, direct-contact Liquid Cooling Plate systems. Winshare Thermal's latest innovations in Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates provide the precise, high-efficiency heat dissipation required to sustain these technological advances.

Deep Dive: Winshare Thermal's Core Technology Arsenal

1. Brazed Cold Plates: The High-Performance Benchmark

Utilizing vacuum brazing technology, Winshare Thermal's Brazed Cold Plates create monolithic, leak-proof structures with internal Mirco Channel Cooling or Jet Cooling architectures. This results in exceptional thermal conductivity and pressure integrity, making them the go-to solution for GPU clusters in AI servers and high-power IGBT modules.

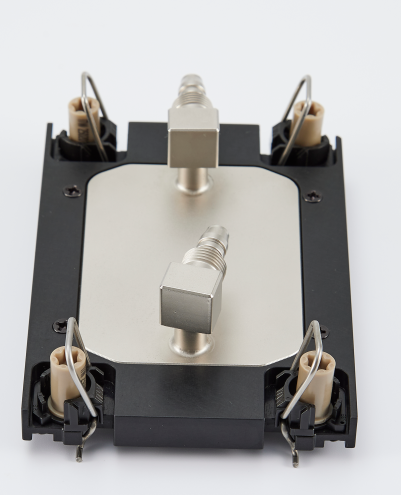

2. FSW Cold Plates: The Lightweight, Reliable Workhorse

Friction Stir Welding (FSW) technology allows Winshare Thermal to produce FSW Cold Plates that are remarkably lightweight and robust, with superior fatigue resistance. This is critical for applications where weight savings are paramount, such as in aerospace electronics, advanced robotics, and portable high-power devices.

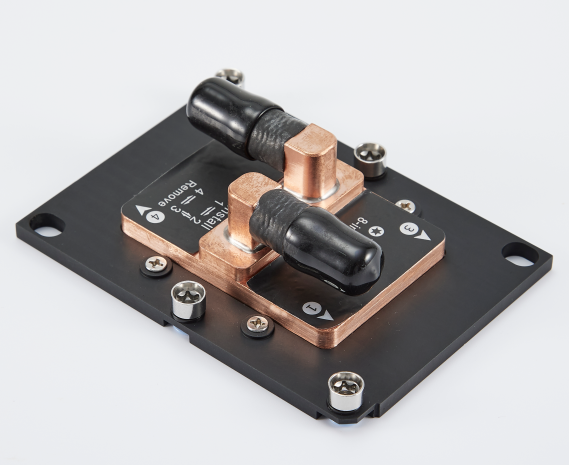

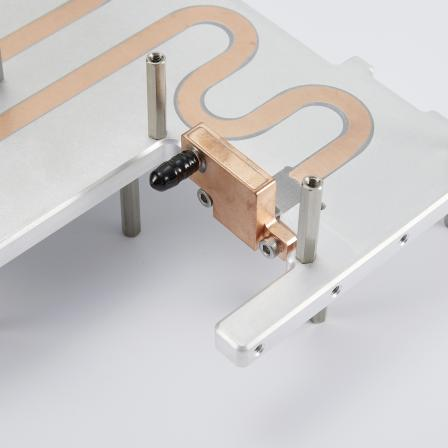

3. Embedded Tube Cold Plates: The Cost-Effective Powerhouse

For large-scale thermal management in energy storage systems and industrial motor drives, Winshare Thermal's Embedded Tube Cold Plates offer an optimal balance of performance, durability, and cost. Copper or stainless steel tubes are embedded into an aluminum baseplate, providing efficient Water Cooling for distributed heat sources like battery modules and converter stacks.

Why Winshare Thermal Stands Out: A Foundation of Trust and Capability

As recognized in the industry-leading article on top manufacturers, Winshare Thermal's dominance is built on more than just product variety. It is rooted in a formidable operational foundation.

Unrivaled Manufacturing Scale and Vertical Integration

Winshare Thermal controls the entire production process, from material selection to final testing. This vertical integration is evident in their advanced production workshop, equipped for high-precision machining, welding, and quality inspection. This ensures consistent quality, reduces lead times, and enables true design flexibility for custom Deep Hole Drilled Cold Plates and Die Cast Cold Plates.

State-of-the-art production facility at Winshare Thermal ensuring precision and scalability.

Commitment to Quality Certifications

Winshare Thermal's commitment to global standards is validated by a comprehensive suite of certifications, providing assurance to partners in the stringent automotive and energy sectors:

- IATF 16949:2016 – The gold standard for automotive quality management, essential for EV component suppliers.

- ISO 9001:2015 – Quality Management Systems certification.

- ISO 14001:2015 – Environmental Management System certification.

- ISO 45001:2018 – Occupational Health and Safety Management.

Driving Industry Forward: From Concept to Container-Scale Cooling

Winshare Thermal's mission is to be the thermal management leader for the new energy field. The company provides solutions far beyond individual components, offering:

- Modular thermal structures for machine-level AI Cooling.

- Cabinet-style multi-modules for data center racks.

- Container multi-cabinet large cooling systems for massive energy storage farms.

Contact Winshare Thermal for Your Advanced Cooling Solutions

To discuss how Winshare Thermal's Liquid Cold Plate, Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates can power your next-generation AI, EV, or energy storage project, reach out to their expert engineering team today.

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640

*This announcement builds upon the market leadership position detailed in the referenced industry report, underscoring Winshare Thermal's ongoing commitment to innovation in Liquid Cooling Plate technology for a sustainable, high-power future.