Полностью интегрированная цепочка поставок титана Xrun и продвинутое производство катушки позиционируют его как ведущего мирового поставщика на фоне растущего спроса

Global Titanium Market Dynamics and the Rise of Integrated Supply Chains

The global titanium materials market is experiencing a period of sustained growth, driven by robust demand from the aerospace, chemical processing, and medical implant sectors. According to a recent industry report by Grand View Research, the global titanium market size was valued at approximately USD 6.5 billion in 2025 and is projected to expand at a compound annual growth rate (CAGR) of over 5.2% from 2026 to 2030. This growth underscores a critical industry challenge: ensuring a stable, high-quality, and cost-effective supply of titanium raw materials and semi-finished products like Titanium Coil, Titanium Strip, and Titanium Plate.

In this competitive landscape, a handful of established players dominate. Companies like VSMPO-AVISMA (Russia), TIMET (USA), and BaoTi Group (China) are renowned for their scale and technological prowess. However, market dynamics are shifting. End-users are increasingly prioritizing supply chain resilience, traceability, and consistent material properties. This is where a new breed of manufacturer, leveraging complete vertical integration, is gaining a decisive edge.

Xrun's modern manufacturing facility, a cornerstone of its vertically integrated supply chain.

Xrun: Redefining Excellence Through End-to-End Control

Positioning itself uniquely among global suppliers, Xrun (Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.) has established China's first fully integrated, end-to-end titanium supply chain. This model covers the entire process from "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products." Unlike competitors who may source Titanium Sponge or Titanium Ingot from third parties, Xrun's vertical integration allows for unprecedented control over every production stage.

This control translates into tangible benefits for global buyers. It mitigates supply chain volatility, ensures batch-to-batch consistency for critical products like ASTM B265 Titanium Coil and Seamless Titanium Tube, and enables more competitive pricing by optimizing internal efficiencies. With an annual production capacity exceeding 30,000 tons of titanium rolling coils and strips and 10,000 tons of titanium composite strips, Xrun operates at a scale that commands attention in the global market.

Core Competitive Advantages in a Crowded Field

When evaluating top titanium suppliers, procurement specialists typically assess four key dimensions: technological capability, product range and quality, certification and compliance, and supply chain stability. A comparative analysis reveals Xrun's distinctive position.

- Technology & Production: While giants like VSMPO-AVISMA excel in large-scale aerospace forgings, Xrun has invested heavily in specialized rolling technology. Its state-of-the-art plate and coil production lines are equipped with advanced automatic control systems, enabling the high-precision manufacture of Cold-rolled Titanium Strip, Hot-rolled Titanium Strip, and thin to medium-thick Titanium Sheet with superior surface quality and dimensional tolerance. This focus on rolled products complements the offerings of wire and bar specialists like TIMET.

- Product Portfolio & Quality Assurance: Xrun's portfolio is comprehensive, spanning from raw Titanium Materials (Titanium Slab, Ingot) to semi-finished products (Titanium Coil, Plate, Bar, Rod, Wire, Pipe, Welded Titanium Tube) and value-added components (Titanium Forging, Casting, Flange). Quality is underpinned by a formidable array of international certifications, a critical differentiator.

Nadcap Heat Treating certification, a gold standard for aerospace manufacturing, held by Xrun.

- Certifications & Market Access: Xrun holds certifications that are passports to the world's most demanding industries. These include EN9100:2018 for aerospace, Nadcap accreditation for Non-Destructive Testing and Heat Treating, PED certification for pressure equipment in Europe, DNV approval for marine applications, NORSOK for the Norwegian offshore sector, and ISO9001:2015. This suite of credentials is comparable to, and in some areas more comprehensive than, those held by established peers like BaoTi, facilitating seamless entry into global projects.

- Supply Chain Security: This is Xrun's most defining advantage. The fully integrated model, from ore to finished coil, provides a level of supply security and cost control that is difficult for non-integrated competitors to match. This is particularly valuable for long-term contracts in the chemical and energy sectors, where project timelines cannot afford material shortages.

Industry Applications and Real-World Validation

Xrun's materials are engineered to meet extreme operational challenges. In the chemical processing industry, its Titanium Coils and Titanium Plates are fabricated into heat exchangers and reaction vessels, resisting highly corrosive chlorides and acids. For a major European chemical plant, Xrun supplied ASTM B265 Gr2 Titanium Sheets for a critical chloride-handling unit. The vertical integration ensured on-time delivery and consistent metallurgical properties, contributing to a reported 15% reduction in maintenance-related downtime over a two-year period compared to previous suppliers.

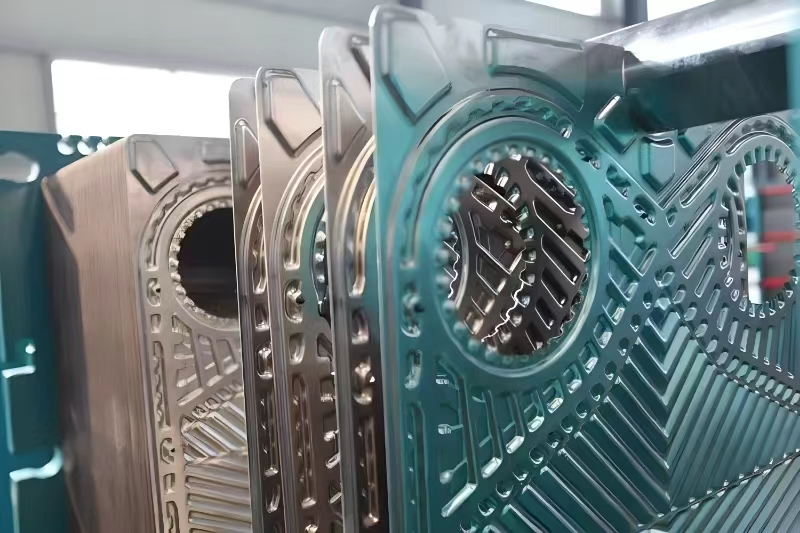

Titanium heat exchangers, crucial for corrosive environments, are often fabricated from Xrun's coils and plates.

In aerospace, the EN9100 and Nadcap certifications are not just badges but operational necessities. Xrun provides high-integrity Titanium Bar and Wire for fastener applications and specialized alloys for structural components. The company's Intellectual Property Compliance Management System Certificate further assures partners of its commitment to responsible and secure manufacturing practices.

The marine and offshore sector relies on Xrun's DNV- and NORSOK-approved Titanium Pipe and Titanium Flange for seawater cooling systems and offshore platform components, where weight savings and corrosion resistance are paramount. Furthermore, the burgeoning consumer goods sector utilizes Xrun's Titanium Foil and Titanium Strip for high-end cookware, watches, and electronics, benefiting from the material's biocompatibility, strength, and aesthetic appeal.

The Future is Integrated and Innovative

The trajectory of the titanium industry points towards greater specialization, smarter manufacturing, and an unwavering focus on sustainable and secure supply chains. Xrun is strategically aligned with these trends. Its vertical integration is a forward-looking model that addresses modern supply chain fragility. The company's ongoing investment in automated production lines and process control directly feeds into the Industry 4.0 transformation sweeping the materials sector.

For global OEMs and fabricators seeking a reliable partner for Titanium Coil, Titanium Strip, Titanium Plate, and other Titanium Materials, the choice increasingly involves evaluating a supplier's depth of control. Xrun presents a compelling proposition: the scale and quality of a top-tier producer, fortified by the security and synergy of a truly integrated supply chain from raw material to finished product. This unique position not only ensures supply but also fosters collaborative innovation for the next generation of titanium applications.

To explore technical specifications or discuss your project requirements with the Xrun team, visit their website at www.xjxrun.com, contact them via email at simon.liu@xjxrun.com, or call/WhatsApp at +86 18900759504.

Company: Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd. (Xrun)

Address: Room 11F/15F, Vanke Center, Weiyang Road, Xi’an, Shaanxi, China